Onboard Hot Bearing Detection and Onboard Flat Wheel Detection

On Board Hot Bearing Detection

Hot bearing Detectors (HBD) are used to measure the temperature of the bearings of a locomotive or a railcar axle thanks to 3C Telemetry's technology.The HBD detects the presence of an overheated wheel bearing and alerts the train crew. A hot bearing can lead to fractures of axle journals that might cause a derailment. With over 1600 derailments per year in North America alone, Hot Bearings are one of the main causes, and can lead to other very dangerous situations as well as significant wear and tear. Reducing HBD events decrease faults and help ensure a safe railway operation. 3C Telemetry LLC is a leader with ONBOARD monitoring for HBD's for locomotives and railcars alike.

Benefits:

- Safety management of railway operations

- Mitigating risks and asset protection

- Improving operational performance by reducing locomotive downtime

- Monitoring

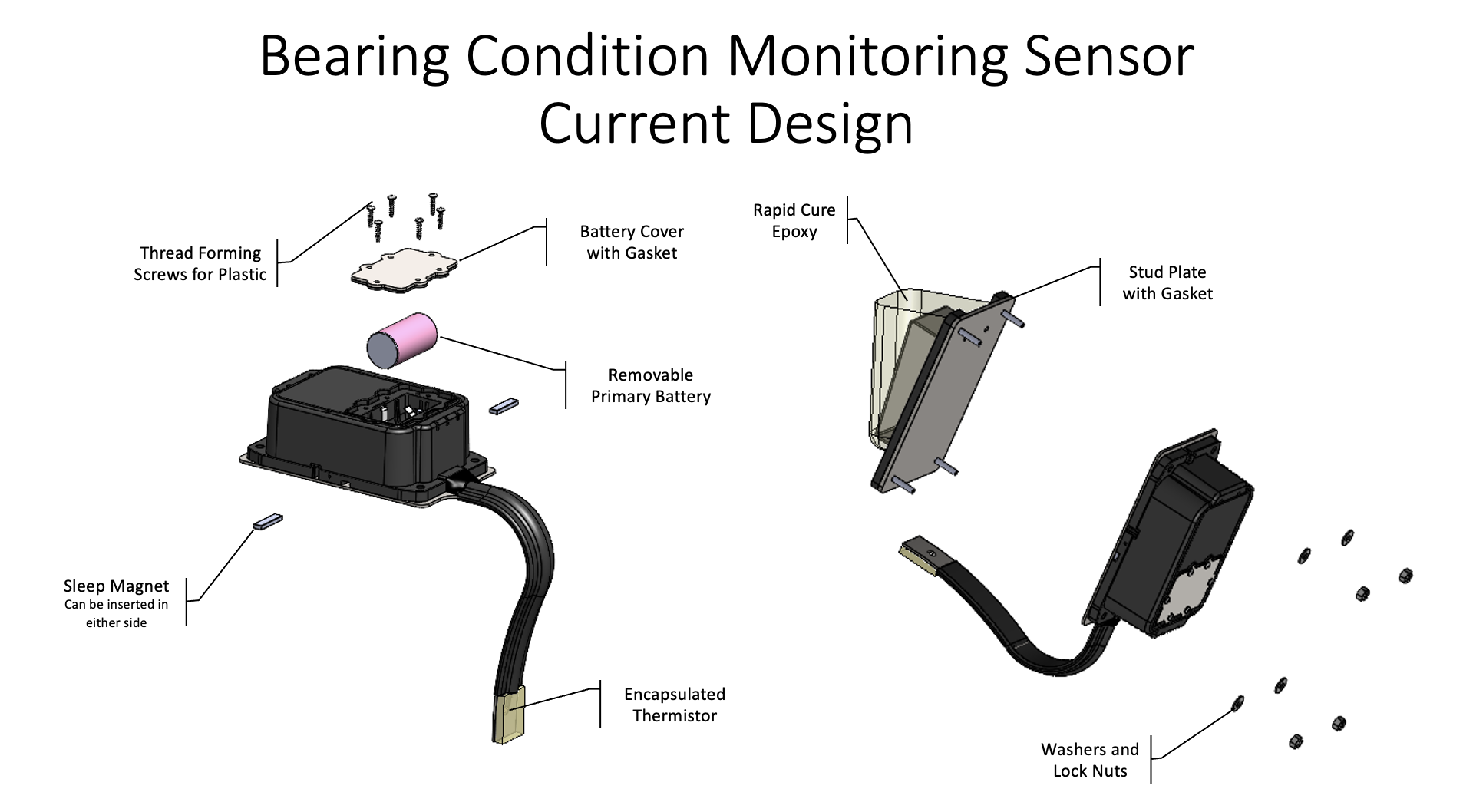

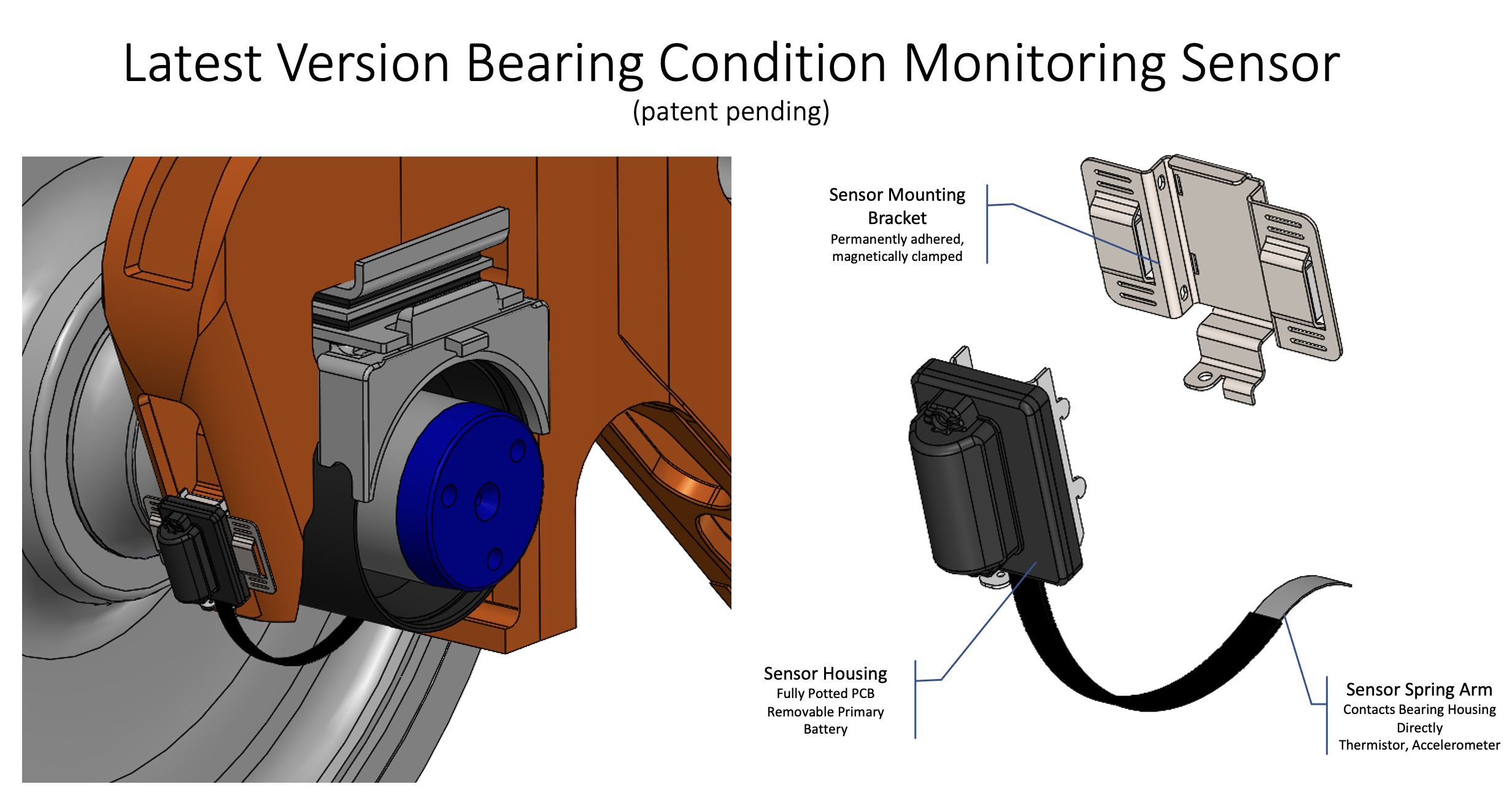

- Unique design that requires no drilling for simple and fast mounting without any adjustment

- Low power consumption

ONBOARD FLAT WHEEL DETECTION

Flat spots are usually the result of excessive braking or conditions that reduce friction between the wheels and tracks, such as diesel spills, chemicals or stormy weather conditions. Wheel flats are more common in autumn and winter because of seasonal factors. Wheel flats are amongst the most common local surface defect in railway wheels, which can result in repetitive high wheel–rail contact forces and thus lead to rapid deterioration and possible failure of wheels and rails if not detected at an early stage. The timely and accurate detection of wheel flats is of great significance to ensure the safety of locomotive and railcar operation and reduce maintenance costs. In recent years, with the increase of train speed and load capacity, wheel flat detection is facing greater challenges than ever. Wheel flats are the most common local surface defect of railway wheels and are one of the important causes of train derailment. With 3C Telemetry's LLC's ground breaking sensor and monitoring technology, the locomotive and railcar industry have a valuable tool to help reduce these incidents.

- Accelerometer in each sensor measure vertical accelerations on a periodic basis.

- Customizable threshholds for RMS and Peak Impacts.

- Both Counters must stay above threshhold for multiple cycles (typically 5 minutes) to trigger flat wheel alarm.